Product Advantages & Features

Performance: Boasting strong power and excellent fuel economy, both power per liter and fuel consumption meet international advanced levels.

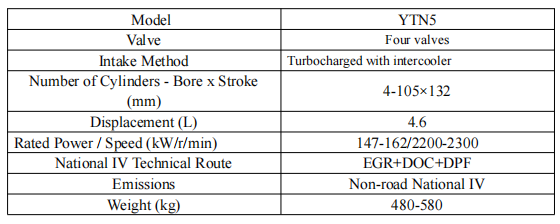

Engine Block Structure: Adopts alloy cast iron cylinder head and block, satisfying the requirement of 200bar high explosion pressure; the cylinder head features four valves per cylinder and a double-layer water jacket, delivering excellent cooling effect for high-temperature four-corner areas; the intake manifold is integrally cast with the cylinder head, achieving optimal coordination between intake swirl ratio and intake coefficient; rear-mounted gear train with integrated design of the gear chamber and engine block.

Low-Pressure Fuel System: 500-hour long-life oil and fuel filters extend maintenance intervals; spin-on filter element enables easy maintenance.

Electronic Control System: Equipped with BOSCH intelligent ECU control system, supporting remote data monitoring and fault diagnosis for peace of mind during operation.

Fuel System: Adopts BOSCH high-pressure common rail system with rail pressure up to 1800 bar-2000 bar, ensuring excellent fuel economy and strong power.

Lubrication & Cooling System: Precision lubricating oil circuit layout and high-efficiency oil pump design deliver excellent lubrication performance; the cooling module integrates water pump, engine cooler, and oil filter into one unit, realizing high cooling efficiency.

Adaptability: Specifically designed for off-road applications, meeting the requirements of various operating conditions such as agricultural machinery and construction machinery; integrated design with compact size, light weight, and streamlined structure facilitates overall engine layout.

Functionality: Optional underhung dual-axis balance device; two rear-end high-load PTO ports; variable fan height to meet different application needs; high-mounted starter motor ensures high safety during field operations.

After-Treatment System: Adopts the EGR+DOC+DPF technical route, requiring no urea during operation; equipped with in-line after-treatment device with vertical installation, facilitating overall engine layout and subsequent maintenance while guaranteeing reliability.